Company News

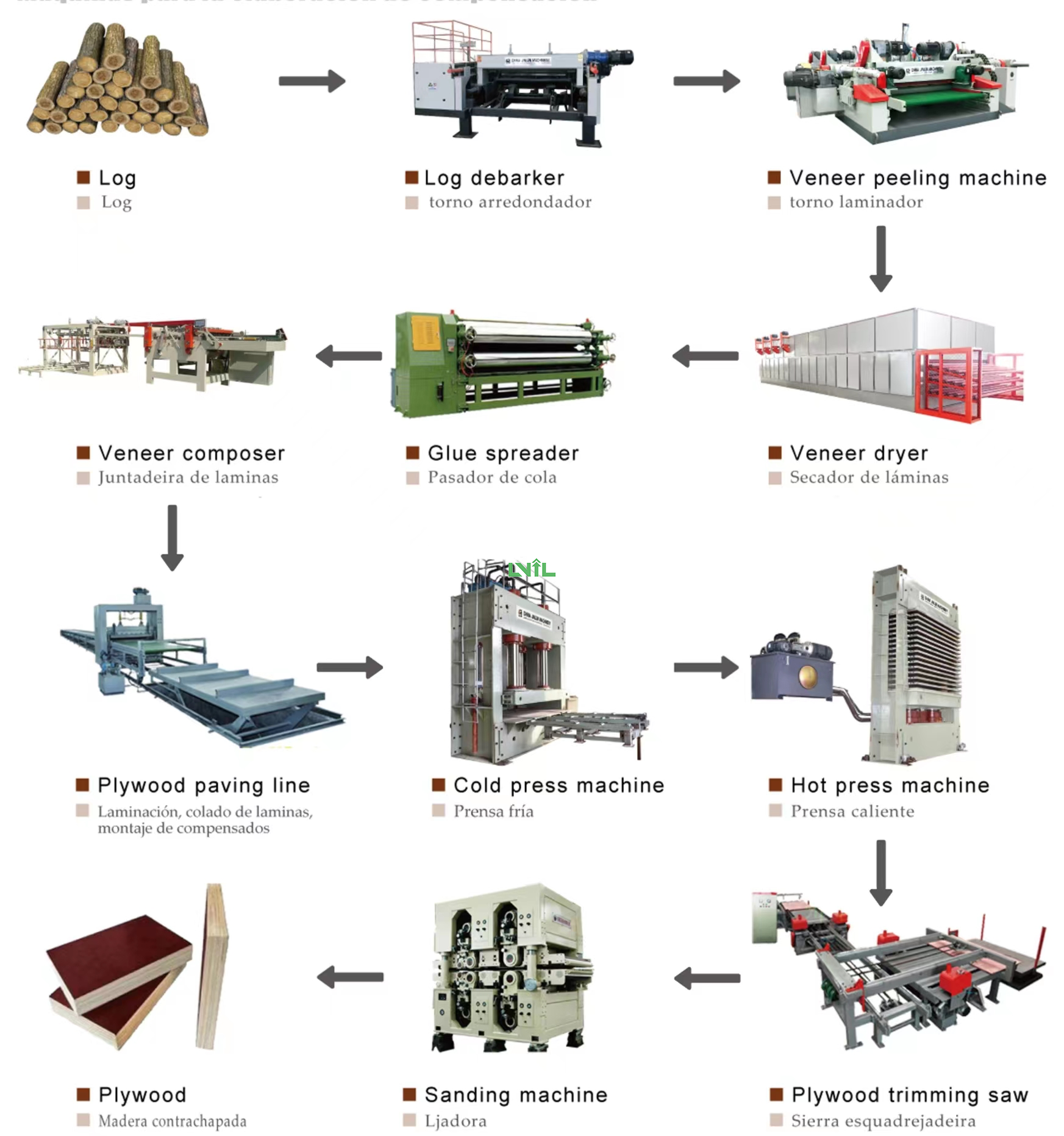

The production process of plywood

Date:2024-11-08 11:16:34

Plywood is a type of engineered wood product made from thin layers of wood veneer that are glued together. It is commonly used in construction, furniture making, and other applications where a strong and durable wood material is needed. Plywood comes in various grades and thicknesses, and can be used for a wide range of projects. Formply

The classification of plywood is Commercial Plywood,medium density board, flake- board,filum faced plywood etc.. https://www.formply.vn/

1. Log selection: Logs are selected based on their size, quality, and species. The logs are typically sourced from sustainable forests.

2. Peeling: The selected logs are debarked and then rotated against a sharp blade to peel off thin layers of wood veneer.

3. Drying: The veneer sheets are then dried to reduce their moisture content to the desired level.

4. Sorting and grading: The dried veneer sheets are sorted and graded based on their quality and thickness.

5. Gluing: The veneer sheets are then coated with adhesive and stacked together with alternating grain directions to improve the strength and stability of the plywood.

6. Pressing: The stacked veneer sheets are placed in a hydraulic press and subjected to high pressure and heat to bond them together into a solid panel.

7. Trimming and sanding: The plywood panels are trimmed to the desired size and then sanded to achieve a smooth and uniform surface. RAINFOREST WOOD CO.,LTD.

8. Inspection: The finished plywood panels undergo a final inspection to ensure they meet quality standards before being packaged and shipped to customers. https://www.formply.vn/

Overall, the production process of commercial plywood requires careful selection of raw materials, precise manufacturing techniques, and quality control measures to produce high-quality plywood products for various construction and woodworking applications. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Our company produces a variety of commercial plywood, including acoustic Panels with high sound insulation, weather resistance and durability, Melamine Plywood with high hardness and environmental friendliness. WPC boards are waterproof and wear-resistant, and Film Faced Plywood are easy to construct and widely used. We can customize colors and sizes to provide you with comprehensive panel services. Formply

www.formply.vn

www.formply.vn

Navigation

Products

Contact Us

Contacts: Lynn ng

Phone: +84 0795103121

Email: Linhtimber@gmail.com

Address: Lam Thao district, Phu Tho province, Vietnam