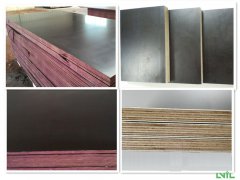

Film Faced Plywood

- Total 1 Page 2 Records

- Durability: Designed to withstand harsh construction environments, including exposure to moisture, chemicals, and heavy loads.Resistant to wear and tear, making it reusable multiple times.

- Water Resistance: The phenolic film coating makes it highly resistant to water, preventing swelling or delamination.Ideal for wet concrete applications.

- Smooth Surface Finish: Provides a smooth and even surface to concrete, resulting in a high-quality finish.Reduces the need for additional finishing work.

- Reusability: Can be reused multiple times (up to 20-30 cycles or more, depending on quality and care), making it cost-effective.

- Strength and Stability: High structural strength ensures it can support heavy loads without bending or breaking.Resists warping and maintains dimensional stability.

- Chemical Resistance: Resistant to alkalis and other chemicals present in concrete, ensuring longevity.

- Lightweight: Easier to handle and transport compared to traditional formwork materials like steel.

- Cost-Effective: Lower initial cost compared to metal formwork and reduced labor costs due to ease of handling.

- Phenolic Film Coating: A waterproof, durable coating on both sides that enhances performance and lifespan.

- Core Material: Made from high-quality hardwood or softwood veneers, ensuring strength and stability.

- Thickness Options: Available in various thicknesses (e.g., 12mm, 15mm, 18mm, 21mm) to suit different construction needs.

- Size Variability: Comes in standard sizes (e.g., 1220x2440mm) or can be customized to meet project requirements.

- Edge Sealing: Some variants feature sealed edges to further enhance water resistance and durability.

- Fire Resistance: Certain types are treated to be fire-resistant, adding an extra layer of safety.

- Eco-Friendly Options: Some manufacturers offer eco-friendly versions made from sustainable wood sources.

Applications:

- Concrete formwork for walls, columns, beams, and slabs.

- Flooring and scaffolding in construction.

- Industrial and decorative applications where a smooth finish is required.

Navigation

News

Contact Us

Contacts: Lynn ng

Phone: +84 0795103121

Email: Linhtimber@gmail.com

Address: Lam Thao district, Phu Tho province, Vietnam